Carbon Fiber and Its Uses Is Various Commercial Purposes

Explore everything about Carbon Fiber

Welcome to the fascinating world of carbon fiber and its diverse applications for various commercial purposes. Carbon fiber, renowned for its exceptional strength-to-weight ratio and durability, has revolutionized numerous industries. From aerospace and automotive to sports equipment and construction, this remarkable material has proven its versatility and performance capabilities.

In this article, we delve into the science behind carbon fiber, its unique properties, and the wide array of commercial sectors that benefit from its use.

Whether you’re an engineering enthusiast or simply curious about this cutting-edge material, join us as we explore the incredible impact of carbon fiber on modern technology and innovation.

Introduction to Carbon Fiber

#1 What Is Carbon Fiber?

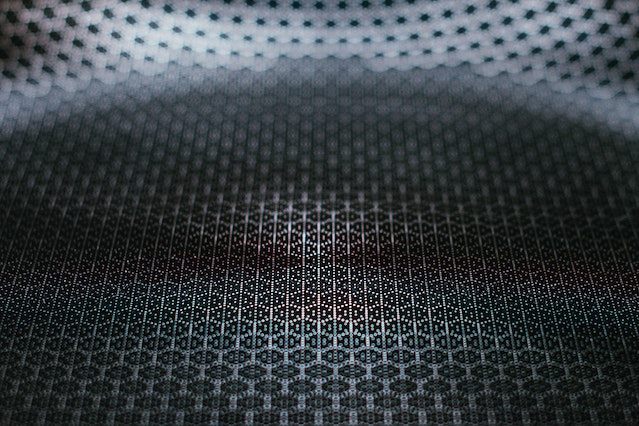

Carbon fiber is a remarkable material, renowned for its strength and lightness, resembling regular cloth but far more advanced. It’s composed of thin strands of carbon atoms, tightly woven into a matrix.

This unique structure grants it incredible mechanical properties and makes it significantly stronger than steel while being remarkably lightweight. Industries like aerospace, automotive, and sports equipment have embraced their potential as it enables the creation of robust, fuel-efficient, and high-performance products.

The carbon fiber’s versatility allows for intricate designs, adding to its allure in various applications. Although it remains relatively expensive, its unrivaled strength-to-weight ratio makes it a prized material for cutting-edge innovations.

#2 Properties & Characteristics of Carbon Fiber

Carbon fiber possesses a fascinating array of properties and characteristics that set it apart from traditional materials. First and foremost, its exceptional strength-to-weight ratio is unparalleled which makes it stronger than steel yet remarkably lightweight.

This attribute grants it excellent structural integrity and enables the production of durable, fuel-efficient products. Moreover, carbon fiber exhibits superb resistance to corrosion and chemicals to ensure long-lasting performance in harsh environments.

Its high stiffness ensures minimal deformation under stress to improve stability. Additionally, carbon fiber is an excellent conductor of electricity and exhibits low thermal expansion to enhance its applicability in diverse industries such as aerospace, automotive, and sports equipment.

#3 Manufacturing Process of Carbon Fiber

The manufacturing process of carbon fiber is a complex and fascinating journey that transforms raw materials into this advanced material. It typically starts with a precursor material such as polyacrylonitrile (PAN) or pitch which contains carbon atoms.

The first step involves spinning these precursor fibers into long strands which are then heated to remove non-carbon elements in a process called stabilization.

Next, the fibers undergo carbonization at extremely high temperatures in an oxygen-free environment. This step removes other non-carbon elements and aligns the carbon atoms to form the characteristic hexagonal lattice structure that gives carbon fiber its strength.

After carbonization, the fibers are usually treated with surface coatings or finishes to improve their performance. The fibers can then be bundled together to form carbon fiber tows which are further woven into fabric or used in other composite materials.

The manufacturing process may also involve additional treatments, like adding epoxy resin to create composite parts or curing processes to enhance the final product’s properties.

This intricate manufacturing process demands precision and expertise, but the end result is a material that revolutionizes industries with its extraordinary strength and versatility.

Advantages of Carbon Fiber in Commercial Applications

#1 Lightweight & High Strength-To-Weight Ratio

The advantages of carbon fiber lie in its lightweight nature and impressive strength-to-weight ratio. Its composition of tightly woven carbon atoms makes it incredibly light, outperforming traditional materials like steel while maintaining exceptional strength.

This unique attribute translates into numerous benefits across various industries. In aerospace, it reduces fuel consumption and enhances flight performance. In automotive applications, it improves fuel efficiency and maneuverability.

Moreover, in sports equipment, carbon fiber provides athletes with tools that are both powerful and agile. Its lightweight quality also eases transportation and handling to make it a favored choice in designing cutting-edge products.

#2 Excellent Durability & Resistance to Corrosion

Carbon fiber offers the advantageous combination of excellent durability and remarkable resistance to corrosion. Its tightly interwoven carbon atom structure provides exceptional strength to withstand extreme forces and impacts.

The robustness of carbon fiber guarantees extended product longevity, minimizing the necessity for frequent replacements. Additionally, carbon fiber’s innate resistance to corrosion protects it from chemical damage and environmental wear.

This feature is particularly valuable in industries where exposure to harsh conditions is common such as marine and aerospace applications. The material’s ability to retain its integrity under such circumstances ensures reliable performance and reinforces its status as a preferred choice for advanced and long-lasting products.

#3 Superior Stiffness & Rigidity

One of the notable advantages of carbon fiber is its superior stiffness and rigidity. The tightly bonded carbon atoms create a highly organized lattice structure which results in exceptional resistance to deformation when subjected to external forces.

This stiffness ensures minimal flexing or bending to provide enhanced stability and precision in various applications. Industries like aerospace, automotive, and sports equipment benefit significantly from carbon fiber’s ability to maintain shape and structure under stress.

Moreover, this property allows engineers to design intricate and lightweight components without compromising on strength. Thus, it contributes to the ongoing advancement of technology and innovation.

#4 Impressive Heat & Chemical Resistance

The advantages of carbon fiber extend to its impressive heat and chemical resistance. It is ideal for applications in environments with extreme heat, like aerospace and industrial settings.

Furthermore, carbon fiber exhibits exceptional resistance to chemical corrosion to protect it from the harmful effects of acids, bases, and various chemicals.

This resilience enables its use in harsh chemical environments such as in chemical processing plants or offshore industries. That is where traditional materials may succumb to deterioration.

Use of Carbon Fiber in Different Industry

#1 Automotive Industry

- Carbon fiber in automobile manufacturing.

- Lightweighting vehicles for improved fuel efficiency.

- Carbon fiber reinforced polymers (CFRP) in car parts.

- Impact on performance, safety, and design.

#2 Aerospace & Aviation

- Carbon fiber composites in aircraft construction.

- Weight reduction and fuel efficiency in airplanes.

- Enhancing structural integrity and safety.

- Carbon fiber in aerospace components and interiors.

#3 Sports & Recreation

- Carbon fiber applications in sports equipment.

- Carbon fiber bicycles and cycling accessories.

- Performance advantages in tennis rackets, golf clubs, etc.

- Carbon fiber in outdoor gear and recreational products.

#4 Construction & Infrastructure

- Carbon fiber in construction materials and techniques.

- Reinforcement and strengthening of concrete structures.

- Lightweight and durable building components.

- Applications in bridges, tunnels, and wind energy.

#5 Marine & Maritime Industry

- Carbon fiber in boat and yacht manufacturing.

- Benefits of carbon fiber in marine applications.

- Resistance to saltwater, UV radiation, and moisture.

- Improving speed, efficiency, and maneuverability.

#6 Medical & Healthcare

- Carbon fiber in medical devices and equipment.

- Orthopedic implants and prosthetics.

- Carbon fiber composites for MRI machines.

- Applications in rehabilitation and assistive devices.

#7 Industrial & Manufacturing

- Carbon fiber in machinery and equipment.

- Tooling and molds made with carbon fiber.

- Applications in robotics and automation.

- Enhanced performance and efficiency in manufacturing processes.

Future Trends & Innovations of Carbon Fiber

The future of carbon fiber technology holds exciting prospects with several advancements on the horizon. As research and development continue, we can expect further improvements in the material’s properties, making it even stronger, lighter, and more cost-effective.

This will open doors to emerging applications in industries beyond aerospace and automotive, such as construction, healthcare, and consumer electronics.

Sustainability will play a key role in carbon fiber’s future, with a growing focus on eco-friendly manufacturing and recycling initiatives. Efforts to reduce the carbon footprint associated with its production and disposal will be prioritized, paving the way for more sustainable practices.

Renewable energy sectors also present immense potential for carbon fiber. As the world moves towards cleaner energy sources, carbon fiber’s lightweight and robust qualities can enhance the efficiency and durability of wind turbine blades and other renewable energy components.

In summary, the future of carbon fiber is promising, with continuous innovation driving its expansion into new industries and sustainable practices ensuring its role in shaping a greener future.

Final Words on Carbon Fiber

Carbon fiber stands as a remarkable material that has revolutionized various industries and continues to shape the future of technology and innovation. Its advantages, including lightweight, high strength-to-weight ratio, durability, resistance to corrosion, and superior stiffness, make it a sought-after choice for a wide range of applications.

With ongoing advancements in carbon fiber technology, we can anticipate even more impressive properties and cost-effectiveness. As its potential expands beyond traditional fields, emerging applications in construction, healthcare, and consumer electronics are on the horizon.

Furthermore, the drive towards sustainability in manufacturing and recycling initiatives ensures carbon fiber’s relevance in an environmentally conscious world. As renewable energy sectors grow, carbon fiber’s role in enhancing efficiency and durability holds immense promise.